What is a SERVO MOTOR?

The word ‘servo motor’ (Lat. ’servire‘, or Eng. ‚to serve‘, also Ger. ‚dienen‘) is a description, not of the construction type, but rather the function of the motor.

Because motors are drive systems, a servo motor describes the function of the pilot motor or actuator, in contrast to the main motor.

As a servo motor, one can therefore in principle use every (here: electrical) motor that is capable of reaching a sufficiently accurate position.

Most types of electric motor constructions require, in addition, an electrical assembly that continuously provides data on the rotor position and/or speed. This information is then sent back to the motor control unit. This generates a closed-loop control. Therefore, when one speaks of a ‘servo motor,’ then they are usually referring to a motor that is suitable for working within a closed-loop control.

The more frequently used stepper motor is, in contrast, not colloquially spoken of in the same category as the servo motor, although in principle it serves the same function.

classification

As a motor-type classification for servo motors, stepper motors, asynchronous motors, synchronized motors, and direct current motors are widely used. As a rule, the motor also has an electronic assembly that continuously produces information on position and/or speed of the rotor. This part is known as feedback.

Under the term motor-feedbacks one finds tacho-generators, resolvers, incremental encoders, sinus-encoders, position feedbacks, and a combination of thereof. In the course of time, impulse wire feedback and Hall-effect devices have become technically obsolete. There are numerous combination possibilities among motor types and feedback styles.

Because the servo motor should reach a precise position, it always needs a superior control unit that receives commands, compares desired values to actual values, and delivers the appropriate electrical current for a given motor. This unit is called controller or servo amplifier.

The stepper motor constitutes an exception. Because the movement of the stepper motor corresponds well enough to the step-count provided by the controller, then – as a rule – any feedback is dispensed with.

Examples in practice

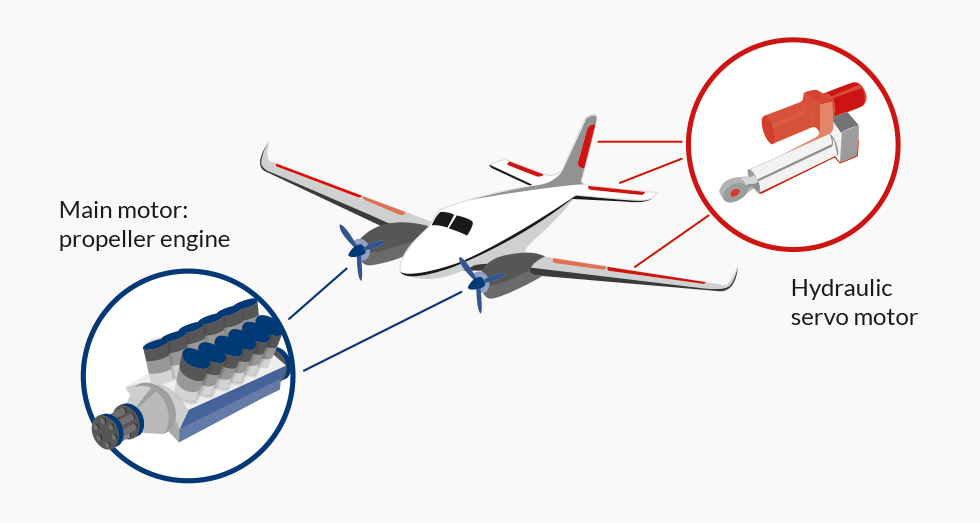

Airplanes: propeller engines (=main motor), actuators for flaps, side-rudders (actuator or servo motors)

Airplanes: propeller engines (=main motor), actuators for flaps, side-rudders (actuator or servo motors)

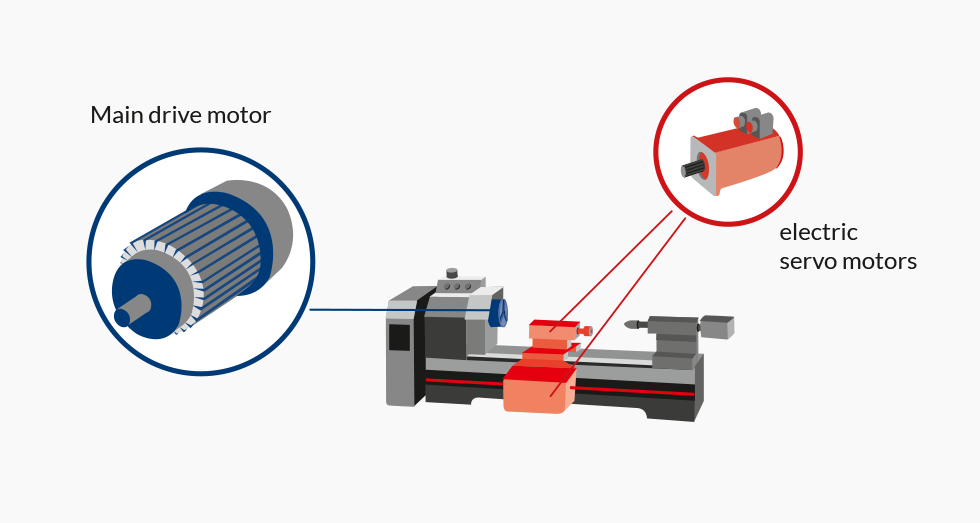

Lathe: work spindle (=main motor), X and Y axes (= servo motor)

Lathe: work spindle (=main motor), X and Y axes (= servo motor)

The term „electronically commutated DC-motor“

The term „electronically commutated DC-motor“ is essentially incorrect. Generally speaking, this is a reference to synchronous motors that cannot be driven by DC-current. In fact, they require an electronic control that is simply powered by a DC-intermediate circuit.